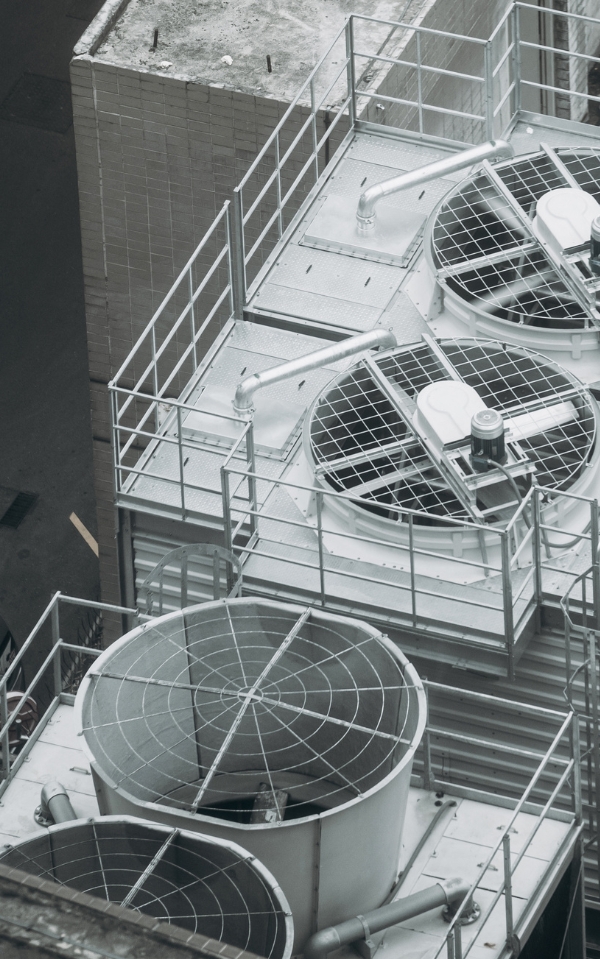

Cooling Tower Maintenance & Servicing

Ensuring Optimal Performance and Efficiency

Regular Cooling Tower Maintenance

Regular servicing prevents costly breakdowns, extends the lifespan of your cooling tower, and ensures optimal performance.

Our Cooling Tower Maintenance Services:

- Belt Drive to Direct Drive Conversion: Increases efficiency, reduces maintenance, and enhances reliability.

- Spray Head Replacement: Restores even water distribution and improves cooling efficiency.

- Noisy Tower Investigations: Identifies and resolves noise issues to prevent further damage.

- Vibration Analysis and Mitigation: Diagnoses and eliminates vibrations to ensure smooth operation.

- Variable Speed Drives (VSDs) Installation: Optimises motor speed for energy savings and reduced wear.

- Sensor Installation for Temperature Regulation: Enhances temperature control for efficient operation.

Common Cooling Tower Issues We Solve

We specialise in addressing these common cooling tower problems:

- Belt Drive Failures: Converting to direct drive systems for improved efficiency and reliability.

- Clogged or Damaged Spray Heads: Replacing and upgrading to restore optimal water distribution.

- Excessive Noise: Diagnosing and resolving issues caused by loose

components, worn bearings, or misalignment. - Vibration Problems: Identifying and mitigating vibrations to prevent structural damage and ensure smooth operation.

Technology for Improved Cooling Tower Efficiency

To ensure your Cooling Towers are running as efficiently as possible, Quantum Plant Maintenance offer installation and optimisation of many key Cooling Tower Components, such as Variable Speed Drives (VSDs), Control Panels, Sensors for precise Speed & temperature control and Vibration Analysis. These vital components can lead to significant energy savings when installed correctly.

Our Equipment includes:

- Variable Speed Drives (VSDs): For motor speed control and energy efficiency.

- Temperature Sensors: For accurate monitoring and regulation of water temperature.

- Vibration Analysis (VA): To detect and mitigate harmful vibrations.

- Thermal Imaging Cameras (TIC): For detecting hotspots and ensuring even temperature distribution.

- Precision Laser Alignment Tools: For ensuring optimal alignment of

components, reducing wear and tear. - Temperature Control Issues: Installing VSDs and Thermistors for precise temperature regulation and energy savings.

- Reduced Efficiency: Implementing upgrades and maintenance to enhance overall performance.

*A worthy mention and a cheaper alternative to improve efficiency on drive would be to redesign the drive transmission using Marine grade Aluminium Pulleys

- These Pulleys can lead to an improvement in efficiency over the standard product and can also increase belt life by as much 2/3!

Common Cooling Tower Servicing Questions

Why is cooling tower maintenance important?

Regular maintenance prevents breakdowns, extends lifespan, and ensures optimal performance and efficiency.

What are some common cooling tower problems you address?

We address issues like belt drive inefficiencies, clogged spray heads, noise, vibrations, and inefficient temperature regulation.

How can technology improve cooling tower efficiency?

We offer installation and optimization of Variable Speed Drives (VSDs) and sensors to save energy and precisely control temperature.