Laser Alignment Services & Solutions

Laser Alignment: Should be an integral part of your “Proactive Maintenance” regime.

Laser alignment is a crucial part of any proactive maintenance plan. It ensures your equipment operates at maximum efficiency with minimal energy consumption. Proper alignment reduces wear and tear, extends equipment life, and lowers operational costs.

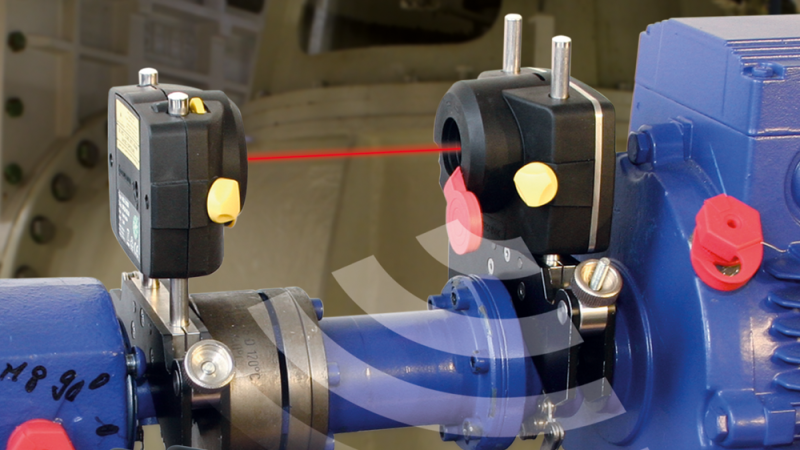

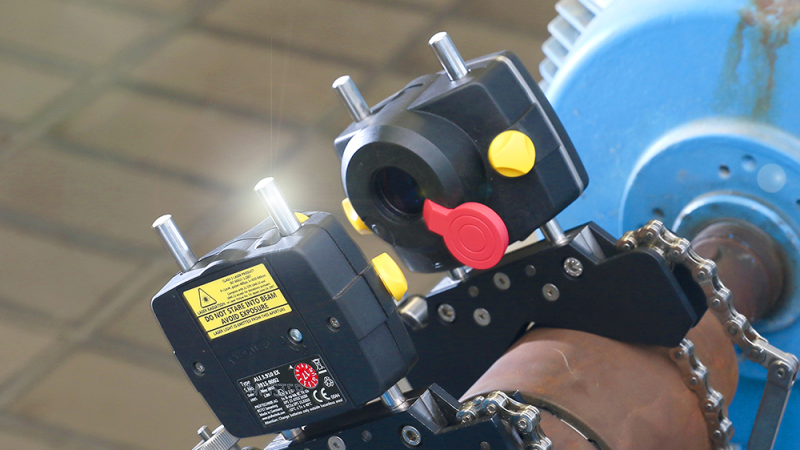

Our Laser Alignment Tools:

- Pruftechnik Rotalign Ultra®: Industry-leading tool for precise shaft alignment.

- Optalign Touch Mobility: Designed for fast, accurate, and mobile alignment tasks.

Alignment Tolerances:

We aim for running tolerances after thermal growth, as follows;

- 4 pole speeds: off-sets not exceeding 0.06mm after thermal growth.

- 2 pole speeds off-sets not exceeding 0.03mm after thermal growth.

Alignment Applications:

We specialise in laser alignment for various types of rotating equipment,

including:

- Pumps: Ensuring peak efficiency and reduced energy

consumption. - Compressors: Precise alignment to minimise vibration and

mechanical stress. - Turbines: Enhancing performance and prolonging the lifespan of

critical components. - Generators: Achieving smooth operation with minimal energy loss.

- Gearboxes: Improving transmission efficiency and reducing noise

levels. - Fans: Optimal alignment for stable airflow and reduced wear

Key Features of Our Laser Alignment Solutions:

- Adaptive Alignment for any maintenance workshop

Single-laser technology sensALIGN 5 featuring continuous SWEEP mode, Live Move, and InfiniRange - Active Situational Intelligence speeds every alignment task

- WiFi and Bluetooth communication

- Continuous SWEEP measurement mode: Automatic collection of alignment data during shaft rotation

- Live Move: simultaneous real-time machine corrections in both horizontal and vertical directions

- Automatic evaluation of the alignment condition (Dynamic Tolerance)

- Soft foot check – measure, correct, and save results

- InfiniRange extends detector measurement range to handle gross misalignment and large coupling separation distances

- Fully featured with all shaft alignment relevant functions

Benefits Our Laser Alignment Services:

- Energy Efficiency: Properly aligned machinery consumes less

power, leading to lower energy bills. - Extended Equipment Life: Reduces wear on bearings, seals, and

other critical components. - Minimised Downtime: Prevents unexpected breakdowns and

costly repairs. - Improved Safety: Reduces the risk of mechanical failure,

enhancing workplace safety. - Environmentally Friendly: Decreases energy consumption,

contributing to reduced carbon emissions.

Why Choose Quantum Plant Maintenance for Laser Alignment Solutions:

- Experienced Technicians: Our qualified team has extensive experience in laser alignment across various industries.

- Advanced Equipment: We use the latest Pruftechnik technology

to ensure precise and reliable results. - Comprehensive Solutions: From initial diagnosis to alignment and post-maintenance checks, we provide end-to-end service.

Common Laser Alignment Questions

What are the benefits of laser aligning a pump and motor?

The main benefits of laser alignment are lowering vibration and power consumption which enhances the longevity of couplings, seals and bearings.

What is soft foot?

Soft foot is when a motor base is not level. When one or more feet are not sitting level, the motor frame can be distorted and alter the air gap in the motor – causing vibration and harmonic noise. This can be addressed during laser alignment.